PS000(A)

Specification::1220mmx1830mm

Thickness::1.8mm

Appearance::Flat on double sides

Transmittance::79%

Color::transparent

Material::PS

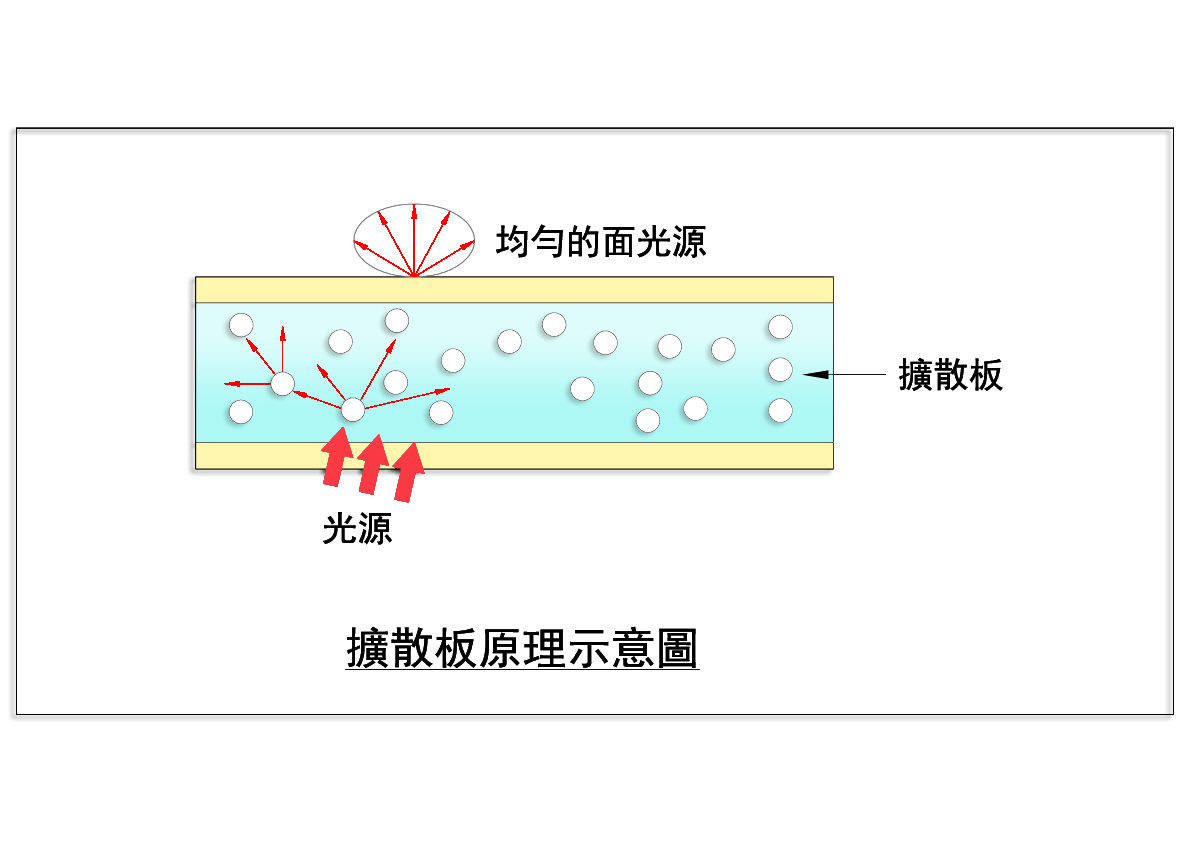

1, The Diffusion Panel :

The theory of making a diffuser sheet is to put the micro-sized diffusion agents into the material like Acrylic PMMA or PS Polystyrene. Due to the differences of refractive rate, when the light go thru the materials, PS or PMMA, after a series of refraction and reflection, the lighting path changes from point light spot into a diffused and enlarged surface light source.

Our diffuser panels can be produced with custom Haze & Transmittance rate.

2, Product Description :

(1). With polystyrene as the base, a variety of dispersible agents were added, and extruded sheet was extruded by extruder.

(2). Product features:

a. Extrusion panel of PS material and with diffused agents added.

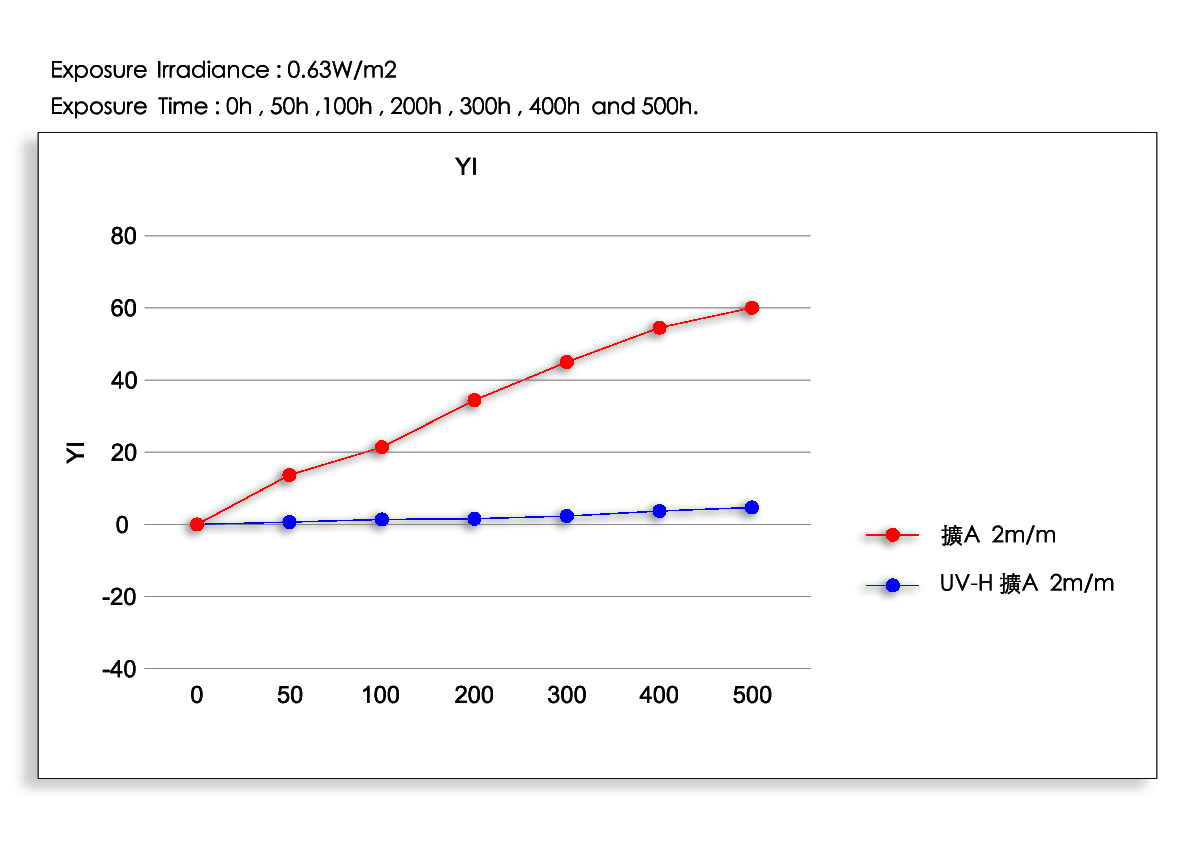

b. PS material has low coefficient of expansion rate, fair yellowing-rate and weather resistance, the best diffuser material for in-door lighting fixtures.

c. Suitable for all in-door lighting fixtures. But, be aware of locations like Chemical material lab or storage spaces, poor ventilation room, and all high temp places are not suggest to use PS diffuser.

(3). A UV stabilizer can be added to prolong the yellowing time.

3, Suggested Application :

Suitable for all Led panel light.

4, Product Series :

Model | Thickness | Specifications | Light transmittance | Materia | MOQ |

| PS000(D) | 1.8mm | 1220mm x 1830mm | 74% | PS | 1T |

| PS000(E) | 81% |

5, Custom Specifications :

Specifications | Material | Width | Length | Thickness | MOQ |

| Customized Availability | PS | 1400mm | unlimited | 1.6-4.0mm | 1T |

Remark:

1. Panels can be cut in specific sizes and shapes if provide with drawings in advance.

2. Panels are using imported diffuse agents to produce, and all flat side with PE protection films.

6, Certification :